- Materials available: AISI 316

- Materials in contact with the liquid:

– Pump head and impeller: AISI 316

– O-ring: EPDM/VITON

– Static shaft: Hastelloy C276

– Bushing: PTFEC/ CARBON GRAPHITE - Flow range: from 0,2 to 7 m3/h (1 -36 usgpm)

- Maximum head: 80 mlc (320ft @ 60 Hz)

- Maximum temperature: 160°C (320°F)

- Maximum viscosity: 200 cSt

- Pressure rating: NP 25 at 20°C

- High-torque magnetic coupling NdFeB standard

- Standard BSP gas threaded in and out connections

- Direct starting motor

- HTA pumps handle 20% entrained gas. Ideal for pumping liquefied gas

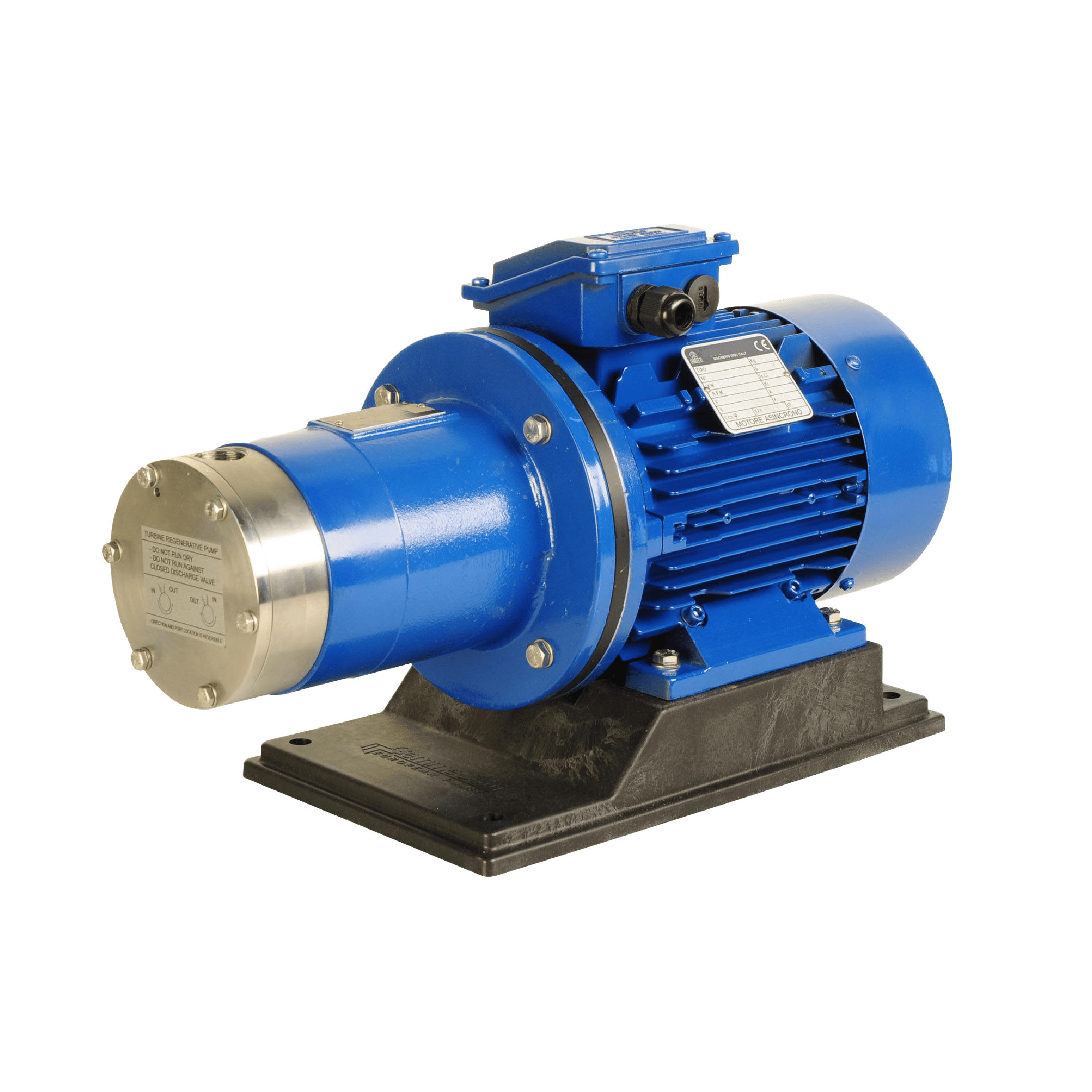

HTA – Magnetic drive turbine pumps in metallic materials

HTA – Magnetic drive turbine pumps in metallic materials

HTA pumps are magnetic drive turbine pumps made of AISI316 suitable to transfer acids, solvents and hydrocarbons. These pumps have been designed with a sealless design where the pump is closed coupled to the motor and the motion occurs through magnetic joints. The external magnet, in fact, is mounted on the drive shaft and it transmits the motion from the motor to the internal magnet connected to the pump impeller which rotates and moves the fluid through the pump. It is the magnetic attraction between the external magnet and the internal magnet which allows the full torque of the motor to be passed to the impeller. The two magnets are separated by a rear casing that creates a hermetic containment of the liquid which has no access to the outside, thereby preventing any leakage of fluid or other fugitive dangerous emissions. Magnetic pumps require minimum maintenance with consequent save in terms of repairing and spare parts costs. Pumps model HTA are available also for Atex zone 2 and zone 1.

MAIN TECHNICAL FEATURES

OPTIONAL

- DIN or ANSI Flanges

- Dry-running protection device

- Baseplate

- Explosion proof motor

- Available in ATEX version for zone 1 II2G and zone 2 II3G (pump mod. EM-T)

PERFORMANCE CURVES 50Hz 2900 RPM