- Materials available: PP/PVDF

- Materials in contact with the liquid:

– Pump head and impeller: PP/PVDF;

– O-rings: EPDM (standard for PP pumps), VITON (standard for PVDF pumps);

– Static Shaft: C40/AISI316

– Mechanical seal: sic/ceramic - Flow range: from 0,5 to 130 m3/h (3-600 usgpm @ 60 Hz )

- Maximum head: 48 mlc (225 ft@ 60 Hz)

- Maximum temperature: 60-70°C for PP and 90°C for PVDF

- Maximum viscosity: 200 cSt

- Pressure rating: NP 6 at 20°C

- Standard BSP gas threaded in and out connections

- Direct starting motor

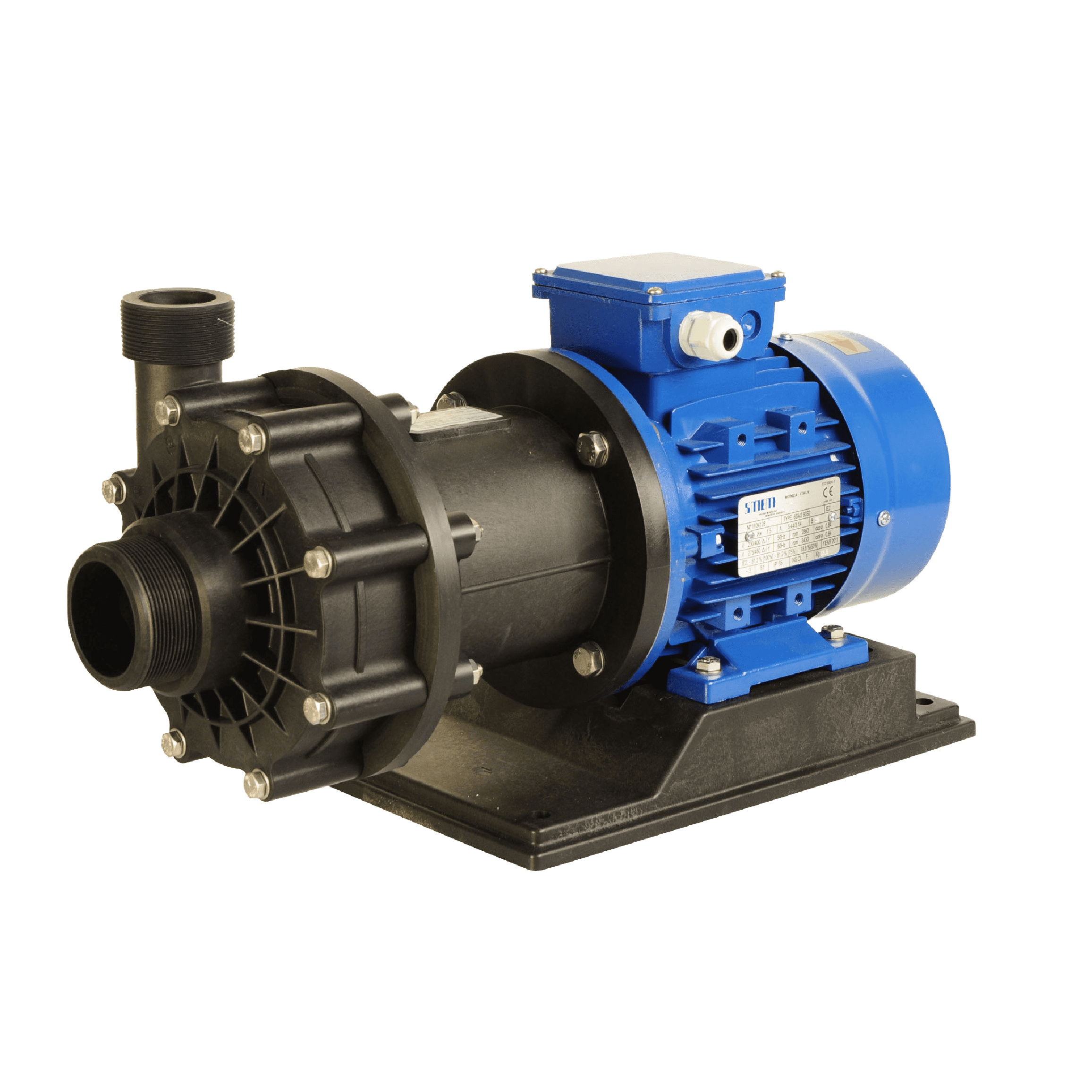

HCO – Mechanical seal centrifugal pumps

HCO – Mechanical seal centrifugal pumps

Mechanical seal centrifugal pumps HCO series, fitted with a mechanical sealing system, are manufactured in thermoplastic materials such as Polypropylene (PP) and PVDF. They are specifically designed for handling highly aggressive and corrosive liquids, even when solid particles are present in suspension.

Several mechanical seal configurations are available, depending on the pump size and operating requirements.

The sealing arrangement differs according to the pump model:

-

HCO 95-10: supplied with a special elastomeric lip seal.

-

HCO 110–170: equipped with an internal PTFE bellows mechanical seal, offered in two material combinations:

-

Standard version: SiC / Ceramic

-

Optional on request: Graphite / Ceramic

-

-

HCO 180–200: available with two alternative sealing solutions:

-

Single mechanical seal in SiC / Ceramic

-

Double back-to-back mechanical seal, with various material options depending on the pumped chemical

-

The double mechanical seal configuration requires an external flushing system.

MAIN TECHNICAL FEATURES

OPTIONAL

- DIN or ANSI 150 Flanges

- Dry-running protection device

- Baseplate (from HCO 95 to HCO 140)

- Available in ATEX version for zone 2 I I 3G (pump mod. EM-CO)

PERFORMANCE CURVES 50Hz 2900 RPM